ASTM D6601: Measuring Cure and After-Cure Dynamic Properties of Rubber Compounds

ASTM D6601 defines the standard method for measuring both the vulcanization behavior and post-cure dynamic properties of rubber using a Rubber Process Analyzer. This powerful technique offers critical insights into a compound’s cure behavior and its mechanical performance under real-world service conditions.

Unfolding ASTM D6601:

ASTM D6601 quantifies how a rubber formulation cures and behaves dynamically after cure. During the test, a rubber specimen is subjected to a sinusoidal oscillation inside a sealed die cavity. The rheometer monitors the torque response over time, recording:

- Elastic torque (Sʹ)

- Viscous torque (Sʺ)

- Complex shear modulus (G*)

- Loss factor (tan δ)

- Among many other critical datapoints

After the cure segment, the system cools to a service-relevant temperature. At that point, the test evaluates the after-cure dynamic response, typically through two strain sweeps to characterize the material’s viscoelastic behavior.

Why It Matters

ASTM D6601 plays a vital role in rubber development, formulation comparisons, and quality control. Unlike conventional cure testing, this method also addresses how the material will behave after vulcanization—providing a clearer picture of performance in the field.

Key Applications:

- Production QC: Monitor batch-to-batch consistency of cure profiles

- Formulation Tuning: Compare processing aids, curatives, or filler systems

- Performance Simulation: Measure stiffness, damping, and strain softening at operating temperatures

- Material Development: Characterize dynamic hysteresis for seals, mounts, isolators, and tires

How It Works:

The test is conducted in two main stages:

- Cure Stage

The uncured compound is oscillated at a constant strain and frequency at the desired vulcanization temperature. The rheometer tracks torque as the rubber crosslinks over time. The cure stage may also be conducted without strain or frequency applied to the sample.

- Post-Cure Stage

After a specified cure time, the temperature is reduced. A strain sweep (or sometimes a frequency or temperature sweep) is conducted to evaluate the dynamic modulus and loss properties at lower, application-relevant conditions.

How to Interpret the Data

Proper interpretation of ASTM D6601 data provides a competitive edge in formulation control and performance forecasting. Here’s what to look for:

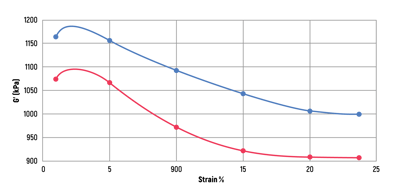

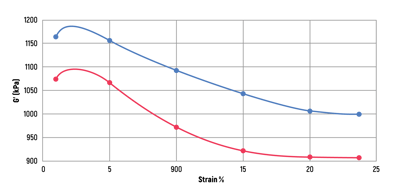

📉 After-Cure Dynamic Sweep

- G* (complex modulus): Reflects total dynamic stiffness

- tan δ (loss factor): Indicates damping or hysteresis—critical for NVH applications

- Payne Effect: Decrease in G' with increasing strain; reveals filler structure breakdown

📊 Strain-Dependent Behavior

Look for:

- A steep modulus drop with strain = poor filler dispersion or unstable structure

- A high tan δ at low strain = desirable damping for vibration control

- A flat G' curve = stable compound, suited for dynamic load-bearing parts. Two strain sweeps are performed. The 2nd sweep is utilized to discern how much “damage” the first sweep caused. It would be assumed that if the 2nd sweep is nearly equal to the first sweep, that the material was not destroyed.

When to Use ASTM D6601

This method is ideal when:

- Dynamic properties matter after cure, not just during it

- You need to simulate how the compound behaves under real service conditions

- You're formulating rubber for sealing, damping, rolling, or high-strain fatigue applications

- You require high-sensitivity testing of changes in compound behavior

Trusted Testing Solutions

At MonTech, we offer Rubber Process Analyzers tailored for ASTM D6601 and similar methods. Our systems feature:

Want to see ASTM D6601 in action? Contact us to schedule a live demo or request application data comparing high-damping and low-hysteresis compounds using this method.