Considerations for Lab Press Design: |

|

|

|

|

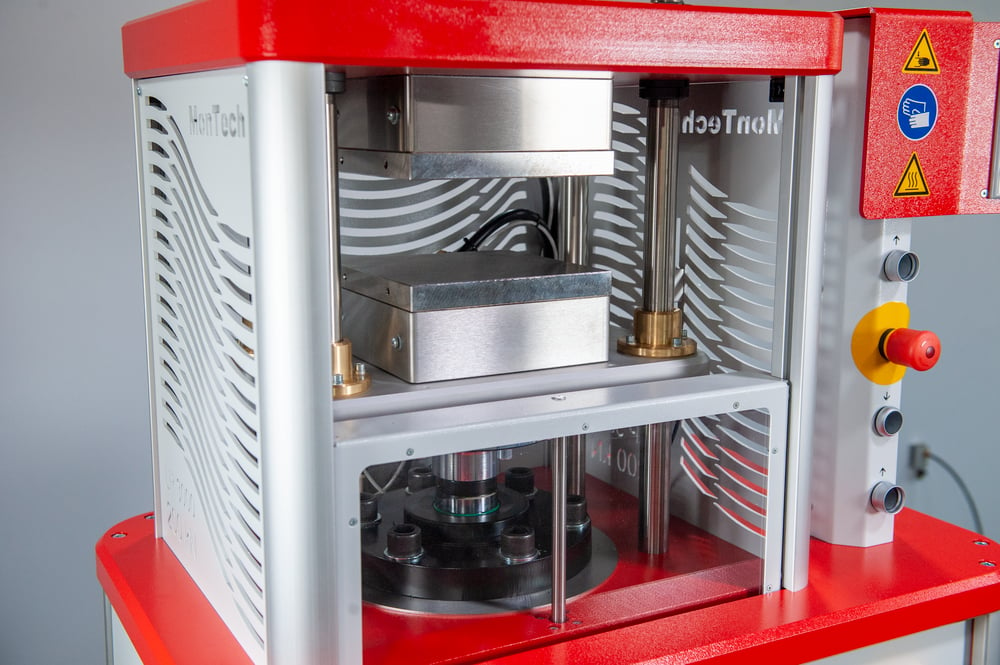

Introduction to Lab Press Selection Demands of rubber laboratories come in all shapes and sizes and the hydraulic curing press remains as one of the staple equipment choices for large or small scale facilities. The importance of the lab press relies on its ability to produce vulcanized samples for continued testing. Some of these tests include, hardness, density, tensile, elongation, Fatigue, DeMattia, optical dispersion and a variety of other test specimens. Test methods as defined within an ASTM or ISO indicate the size and shape of the sample required to complete the standardized test. Knowing what to look for when selecting the correct design and build for your needs can be difficult. In this eBook, it is our goal to help simplify the basic questions any laboratory must ask in order to engineer the correct press model for specified applications. |

|

|

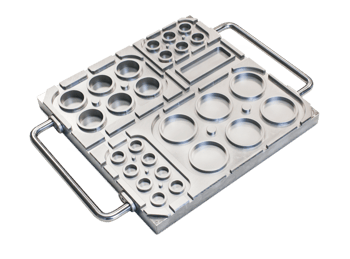

Molds Having the right mold or molds is a vital part of the equation. Molds must provide all the necessary test standard cavities required for laboratory testing while also fitting inside the platen dimensions. MonTech offers a comprehensive range of durable curing molds according to any ISO, DIN, ASTM and GB standard. Manufactured from hardened and polished stainless steel, molds feature single or multiple cavities, and can be customized for unique shape and dimension requirements. The molds are designed to withstand extreme amounts of force and to provide uniform temperature distribution, ensuring the samples produced are reliable for the tests in which they are to be used. |

|

Operation |

|

|

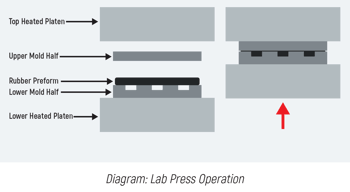

Lab Press Operation The principles behind operating a lab press are straight forward and easy to understand. To begin the vulcanization procedure, the mold is placed between the pre-heated platens. Next, users will typically close the upper and lower platens to pre-heat the entirety of the mold to create a uniform mold temperature. This allows for homogeneity in sample curing.

Once the press platens and molds are at operating temperatures, the rubber preform(s) are be placed between both plates. From here, the press is activated, slowly closing the platens to squeeze the mold plates and preform(s) together. The rubber flows into the sample cavities of the mold while the vulcanization process begins. Bump timers may be used during this phase of operation to degas or vent trapped gas.

After the curing cycle is complete, users then raise the platens, open the molds and extract the samples. Samples may then go directly into processing of physical testing or otherwise. |

|

|

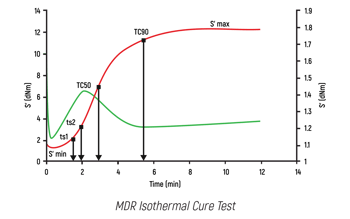

Curing times and temperatures are calculated by using an MDR isothermal test. This test produces the cure curve and it’s corresponding data points. The most important points to measure are ML, MH, TS 1, TS 2, TC 10, TC 50, TC 90. |

|

Building a Lab Press |

|

|

Follow the Standard: For the most uniform samples, make sure the lab press build follows the ASTM or ISO standard specifications: • Thermal accuracy and distribution (± 0.5°C) • Specific platen force (3.5 MPa) • Platen parallelism (0.25 mm/m or better) • Flawless platen surface quality • Usable platen area All MonTech lab presses meet or exceed the parameters above.

Selecting the Right Press and Molds The manufactured products, the testing laboratory, regulatory requirements, specific test required, and the magnitude of testing required all influence the laboratory press requirements. Laboratories must select a lab press for installation and choose a mold design that is right for their testing requirements. The demand for highly customized lab presses has rapidly increased in recent years due to a wide array of needs of laboratories, depending on their scale and testing applications. With over three dozen options for MonTech presses, picking and choosing the correct sizes and modules can be a daunting process for the lab manager or capital planners. Outlined below are a variety of considerations for determining the correct hydraulic press build: |

|

|

Picking the Correct Size Press MonTech supplies press sizes reaching up to 150 tons. However, not every laboratory requires such high capacity of force. It is recommended that the test standards be reviewed (i.e. ASTM D 3182 or ISO 2393), and a calculated throughput of samples is determined. If molds have been previously engineered, then picking a press matching the mold size is also advisable. Modifications to press stroke may also be made based on the vertical height of the mold.

Daylight Options Daylight is defined as the space between upper and lower platens. This can also be interpreted from the stroke height of the press. This limited space of the daylight is the maximum amount of room for mold placement. Here, users may choose to have multiple daylights (multiple platens) or increase the stroke of the press to accommodate larger molds or improve press ergonomics.

For the majority of MonTech presses, single, double, or triple daylight options are available for selection. Laboratories considering multiple daylights for their lab press typically select this option due to increased throughput, floor space saving, and long-term cost savings. |

|

Temperature Ranges For some applications, temperatures must reach higher than standard models. Base temperatures for MonTech presses may reach up to up to 250°C (480°F). Applications for plastics and composites may range from 300°C to 500°C. |

|

|

Heating Zones In some applications, particularly with sensitive materials or specialty molds, the heat uniformity or distribution becomes extremely important. Specific heating zones may be engineered into the lab press platens to increase press temperature homogeneity. Additionally, heating zones may be placed in other areas of the platen to ensure more or less heat is applied to a specific area in the mold. |

|

|

Cooling Options Cooling options are needed for many plastics applications to aid in post-flow solidification of the material. Open and closed loop cooling systems are available |

|

|

Low Pressure Options Low pressure options are available for specific applications. Not all compounds require high amounts of pressure to create optimum test specimens. Some of the applications that should consider low pressure options include: Delicate molds, silicone materials, tire thread testing, and blow point determination of foaming/sponging materials. |

|

|

Considerations for High Production Labs Outfitting lab presses with ergonomic or automation options is an excellent way to deal with high workloads more effectively. MonTech provides a substantial number of options for increasing throughput of lab presses. |

|

Production Options |

|

|

Fixed Molds Fixed molds must but considered if the top and bottom of the mold must meet perfectly. This is especially important with sliding or tilt molding. |

|

|

Sliding Platens After a press vulcanizing cycle is complete, operators may then slide out the mold on a carrier platen. Molds must be fix mounted. Sliding platens may be used on either the upper or lower press platens. |

|

|

Tilting Platens Similar to sliding platens but instead the platens are hinged, allowing upper and lower platens to tilt downward for better access to the mold. |

|

|

Platen Shuttles Platen shuttles may incorporate either sliding or tilting platen designs, automating the sample extraction process. |

|

|

Sample Ejection Systems Pneumatic, hydraulic, or mechanical. Ejection systems push vulcanized samples from their original cavities. |

|

|

Press Table Allows the mold to be slid onto an attached table for more ergonomic sample extraction. |

|

|

LED Status Signal Tower Signal towers containing green, yellow or red lights may be installed to indicate to operators the completion of a test or the ready-status of a press. |

|

Safety Features |

|

|

Considerations for Safety Different countries, states, or otherwise rely on specific safety standards or codes to ensure working protection. Examples of these safety standards include CSA, UL, OSHA and others. All MonTech lab presses are compliant with all international safety standards.

In addition, optional safety features include: |

|

|

Light Curtains Placing light curtains before the daylight entrance ensures the operator is clear of the press before starting the next press cycle. |

|

|

Alarm Systems Alarm systems allow for visual and audible signals for determining the completion of a test. They may also be installed to warn the user that a safety or operational protocol was not followed. |

|

|

Platen Lighting LED lights may be optionally installed to provide working light to users within the daylight operating area of the press. |

|

|

Gates or Shields Additional gates and shields can be custom outfitted into the machine design. |

|

|

Temperature Safety Limiters Prevent any over temperature malfunction occurring in a press such as damage to the platens due to temperature control runaway. |

|

|

Customized Safety Features MonTech engineers readily accommodate preferred safety features specified by any customer. |

|

Conclusion |

|

|

Making the Choice There are many things to take in to consideration when selecting a press build and options for your laboratory press. Between testing applications, production scale, international standards, efficiency and cost considerations, and safety concerns - the list of items to consider can appear to be never-ending. The team at MonTech is here to provide as much assistance as needed in making these choices. Our top priority is assuring that you have exactly what you need for testing, so your business can continue to be successful and productive. |

|

|

|